Exposing Screens, Creating Goods

August 12, 2024 - 2 min read

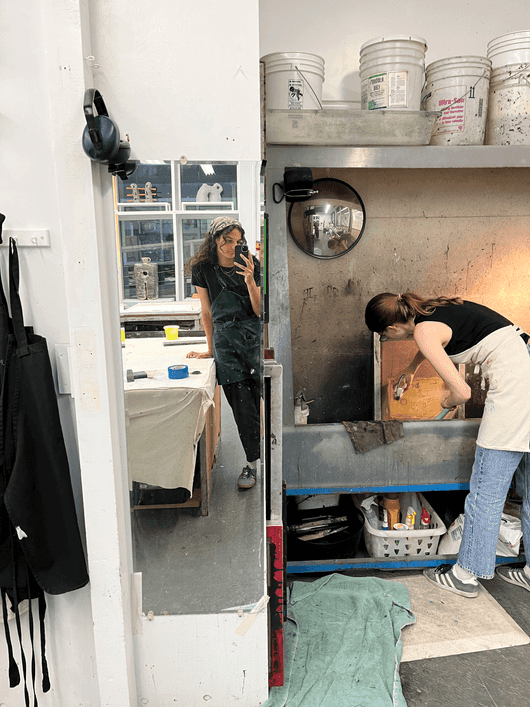

One day I will have a studio in my garage. It will have every possible tool in the world and a computer that somehow has the most seamless usable creative software imaginable that means I will never have to open photoshop again. Until then, when I decide my favourite quote from my running group Lost Boys needs to be on tote bags and my mechanically-inclined high school best friend asked me for gym t-shirt recommendations I am forced to find a workshop/studio/lab that can support my need.

Here's a quick rundown! Mesh count depends on level of detail in your design. I used 156. 96 pixels per inch. Unless you're doing serious industrial work on textiles the standard is around 110. Set the frequency of the halftone on your bitmap file to 1/5 of the mesh count. General baseline for time in the exposure unit is 60 seconds.

And then, the flow goes like this:

- Flood print

- Pressure back

- Pressure Forward

- Dry run

As a side note, I actually hate Adobe products. What few understand about products is people don’t just want a powerful feature. And they certainly don't just want a perfect feature. An unnecessary, undesirable feature, even when very functional, won't connect. A very powerful necessary feature, when not functional or too customizable, won't connect. The most difficult thing is figuring out what to actually build for, it's never as simple as "customers need x." Customers want the ability to execute a process without friction. Once you figure out what to build for, only then does it have to be executed on precisely. Understanding the customer, building relationships with them, and keeping them engaged is something Adobe simply avoid doing. But anyway, enough about my product musings! Screenprinting is fun! After you've done all the file preparation and hopefully haven't had to sacrifice elements of your design in the process!